Unit of Production Method Depreciation Explained

As with any accounting or tax-related decision, consulting a professional tax advisor can help ensure compliance with IRS regulations and optimize your business’s financial situation. The Unit of Production Method assumes that an asset will have zero residual value at the end of its useful life. For example, some assets may have a residual value that is higher than zero, such as real estate or machinery. In such cases, the Unit of Production Method may overestimate the depreciation expense, leading to an understatement of the asset’s value on the balance sheet. This provides a more accurate representation of the company’s expenses and revenue, which can ultimately lead to better decision-making.

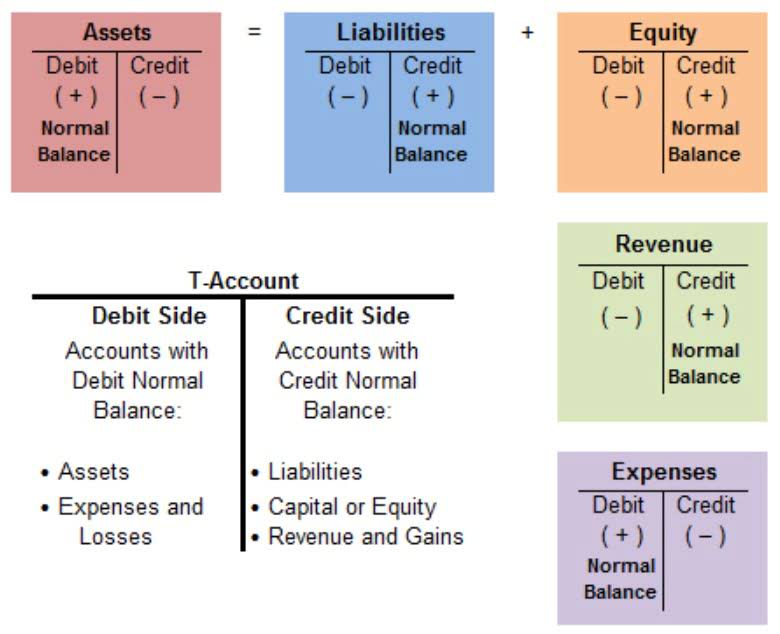

As the asset is worn down by wear and tear, technology, obsolescence, depletion, decay, rot or inadequacy, both the cost and value of the asset is written off on the balance sheet. There are several different ways to account for deprecation, and units of production is one of them. Let’s say you own a printing press that cost $100,000 and has an estimated useful life of 10 years and a total estimated production of 1,000,000 copies. To calculate the depreciation expense for the first year, you would divide the total cost by the estimated production, giving you a cost per copy of $0.10. If you produced 100,000 copies in the first year, your depreciation expense would be $10,000 (100,000 x $0.10). This calculation would be repeated each year until the asset is fully depreciated.

- Additionally, this method is easy to understand and apply, making it a popular choice for many industries.

- It is a method that calculates depreciation based on the actual usage of an asset, rather than its age or expected lifespan.

- The formula involves multiplying the book value by double the straight-line rate, resulting in higher depreciation deductions at first.

- The primary advantage is efficiency, while the main limitation is inflexibility to changing specifications or custom orders.

If you drove the truck 10,000 miles in the first year, your depreciation expense would be $5,000 (10,000 x $0.50). Again, this calculation would be repeated each year until the asset is fully depreciated. For example, let’s say a company owns a machine that is used to manufacture a product. The company estimates that the machine will produce 100,000 units over its lifetime. However, if the machine is used less frequently than expected, the company may end up overestimating the total usage and underestimating the depreciation expense. The Unit of Production Method is a depreciation method used by businesses to allocate the cost of an asset over its useful life.

By using the Unit of Production Method, the farmer can calculate the cost of producing each batch of corn by dividing the total cost of production by the amount of corn produced. It is best suited for assets that are used at varying rates throughout the year, such as vehicles or manufacturing equipment. For assets that are used at a constant rate, such as buildings or land, other depreciation methods, such as the straight-line method, may be more appropriate. Finally, using the Unit of Production Method can provide tax benefits for the company. This method allows for a more accurate representation of the depletion of natural resources, which can lead to a lower tax burden for the company. This is because the company is only taxed on the revenue generated from the sale of the products produced from the resource, rather than the entire value of the resource.

It is a method that focuses on the actual usage of the asset rather than its age or lifespan. This blog section will provide an in-depth guide on how to calculate depreciation using the Unit of Production method. Overall, the Unit of Production Approach is a useful accounting method for industries where the cost of production varies significantly with production volumes. It accurately reflects the cost of production and is easy to understand and apply. However, it requires accurate tracking of production volumes and may not be suitable for industries where the cost of production does not vary significantly with production volumes.

By employing this technique, businesses can effectively claim larger depreciation deductions during years in which a particular piece of equipment experiences higher productivity levels. As a result, these companies can better manage their cash flows and accurately account for the cost of maintaining their assets (Bartholet, 2017). The unit of production method’s unique approach to depreciation can significantly influence a company’s financial statements, offering a more dynamic reflection of asset value. By tying depreciation directly to the asset’s usage, this method ensures that the expense recorded on the income statement aligns closely with the actual wear and tear experienced by the asset.

How Does the Unit of Production Method Affect Accounting?

Despite its advantages, it still lacks the direct correlation to asset usage that the unit of production method offers. When evaluating the unit of production method against other depreciation techniques, it’s important to consider the specific circumstances and needs of a business. The straight-line method, for instance, is one of the most commonly used approaches due to its simplicity and ease of application. This method spreads the cost of an asset evenly over its useful life, making it straightforward to calculate and predict.

Calculating Depreciation Expenses using the Unit of Production Method

- Evaluating what production methods are and how they affect operations helps managers identify which processes are best suited to their products, resources and market demands.

- Companies need to keep detailed records of the number of units produced or consumed by the asset, which can be time-consuming and prone to errors.

- Advantages include predictable output and efficient resource use, while disadvantages include limited flexibility for customization.

- The unit of production method is useful for businesses that require a more accurate estimation of the asset’s value over time, especially for assets that are heavily used or have a short useful life.

- This could be measured in units produced, hours operated, or any other relevant metric that accurately reflects the asset’s usage.

The company estimates that the equipment will produce 10,000 units over its lifetime. However, if the equipment breaks down or is used less frequently than expected, the actual usage may be lower than the estimated usage. This can result in depreciation expenses that are too high, which can affect the company’s financial statements. One of the main disadvantages of the Unit of Production Method is the difficulty in estimating usage. This can be difficult to estimate accurately, especially for assets that are used irregularly or in varying amounts. For example, let’s say a company purchases a machine for $100,000 that is expected to produce 100,000 units over its useful life.

The Unit of Production Method is just one of several methods of calculating depreciation expenses. Other methods include the Straight-Line Method, double-Declining Balance method, and sum-of-the-Years-digits Method. Each method has its advantages and disadvantages, and the choice of method depends on the company’s specific needs and circumstances. However, the Unit of Production Method is often preferred in industries where the asset’s usage is directly proportional to the output produced. To calculate depreciation expenses using the unit of production method, you need to determine the total number of units that the asset is expected to produce over its useful life. Then, you divide the cost of the asset by the total number of units to get the cost per unit.

Sum-of-Year’s Digits Depreciation Method

For example, manufacturing equipment or machinery often follows the unit-of-production principle, as their efficiency and productivity decrease with each unit produced. This method can result in a more accurate reflection of the asset’s value over its life cycle. While each depreciation approach has its advantages and disadvantages, understanding their differences can help businesses optimize their tax strategies. The unit of production method can be contrasted with the Modified Accelerated Cost Recovery System (MACRS), another popular tax-based approach for calculating asset deprections. While MACRS methods utilize time elapsed as their primary factor, the unit of production method focuses on the actual number of units produced.

This can lead to more accurate profit margins, particularly for businesses with fluctuating production levels. For instance, during periods of high production, depreciation expenses will be higher, which can offset increased revenues and provide a more balanced view of profitability. The Unit of Production Method is a popular way of calculating depreciation expenses for businesses that use their assets based on the number of units they produce. This method is commonly used in industries such as manufacturing, mining, and agriculture where assets like machinery, equipment, and vehicles are used to produce output. The Unit of Production Method is a practical approach to calculate depreciation expenses as it is based on the actual usage of the asset rather than its age or time of use.

However, it may not be suitable for industries where the cost of production varies significantly with production volumes. Another method is the Last-In-First-Out (LIFO) method, which assumes that the last units produced are the first to be sold. The LIFO method is useful in industries where there is a high inflation rate, as it allows companies to account for inflation in their cost of goods sold.

The residual value is subtracted from the asset’s cost to determine the total depreciation expense. Maintenance and repair costs are also crucial factors to consider when using the Unit of Production Method. As the asset is used or produces more, it may require more maintenance and repairs, which can affect the depreciation expense. For example, suppose a company purchases units of production method a machine for $100,000 that it expects to produce 50,000 units over its useful life.